Isikhwama sikaMechanical Shear Bolt Lug

Uhlolojikelele

Amatheminali e-torque aklanyelwe ngokukhethekile ukuphatha ukuxhumana phakathi kwezintambo nemishini.

Indlela eyingqayizivele ye-shear bolt inikeza indawo yokuma engaguquki futhi enokwethenjelwa.Uma kuqhathaniswa namahhuku okugezwa kwendabuko, ishesha kakhulu futhi isebenza kahle kakhulu, futhi iqinisekisa umzuzu wokugunda onqunyiwe kusengaphambili namandla okucindezela.

Itheminali ye-torsion yenziwe nge-tin-plated aluminium alloy futhi inodonga lwangaphakathi olumise okwe-groove.

Isici esiphawulekayo ukuthi singasindisa abasebenzi futhi sithuthukise ukusebenza kukagesi kanye nemishini.

▪ Impahla: ingxube ye-aluminium ethini

▪ Izinga lokushisa lokusebenza: -55℃ kuya ku-155℃ -67 ℉ kuya ku-311 ℉

▪ Okujwayelekile: GB/T 2314 IEC 61238-1

Izici nezinzuzo

▪ Uhlu olubanzi lwezinhlelo zokusebenza

▪ Umklamo ohlangene

▪ Ingasetshenziswa cishe nazo zonke izinhlobo zamakhondakta nezinto zokwakha

▪ Ukugunda njalo kwe-torque nati lekhanda kuqinisekisa ukusebenza kahle kokuthinta ugesi

▪ Ingafakwa kalula ngesikrufu sesokhethi esijwayelekile

▪ Idizayini eyakhelwe ngaphambili ukuze ifakwe kahle kakhulu kumakhebuli kagesi aphakathi nendawo afika ku-42kV

▪ Ikhono elihle lomthelela wamanje lamanje kanye nelimelene nesikhathi esifushane

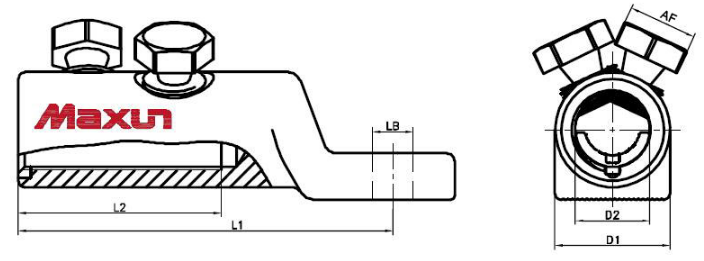

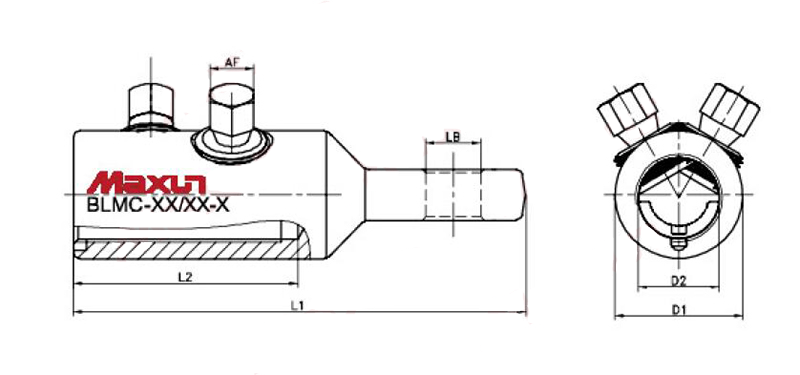

Uhlolojikelele

Umzimba wetheminali wenziwe ngengxube ye-aluminium ene-tin-plated high-tensile.Itheminali ilungele izinhlelo zokusebenza zangaphandle nezangaphakathi, futhi inganikeza ukucaciswa kosayizi ohlukile.

| Izici nezinzuzo zama-lugs mechanical nezixhumi | Umsebenzi |

| Ibanga lohlelo lokusebenza olubanzi nokuguquguquka okunamandla | Isibonelo, imininingwane emithathu ingamboza ama-conductor angu-25mm2 kuya ku-400mm2, |

| Umzimba wenziwe nge-high-tensile tinned aluminium alloy | Futhi ingasetshenziswa cishe nazo zonke izinhlobo zomqhubi nezinto ezibonakalayo. |

| Amabhawodi enziwe nge-aluminium alloy ekhethekile | Izici ezinhle zokuxhumana, zingakwazi ukubona ukuxhumana phakathi komqhubi wethusi kanye nomqhubi we-aluminium. |

| Umklamo ohlangene | Kudingeka kuphela indawo encane yokufaka, elungele izinhlelo zokusebenza ezinkulu. |

| Idizayini ye-Tubular spiral ngaphakathi komzimba ukuthuthukisa ukusebenza kokuxhumana | Ukusebenza kahle kagesi. |

| Imbobo emaphakathi bese ufaka | Isendlalelo se-conductor oxide siyahlukaniswa. |

| I-torque shear head nut njalo | Ucezu lwe-plug-in lulungisa usayizi owodwa wokuxhuma noma itheminali efanele izinhlobo eziningi zezintambo. |

| Nati eligcotshiwe | Okufakiwe kusiza i-conductor ukuthi igxile kangcono futhi ngeke ikhubaze i-conductor uma ibholithi iqiniswa. |

| Izici ezikhethekile zamatheminali emishini | |

| Isibambo eside | Ngobude obude obengeziwe, ingasetshenziswa njengesithiyo somswakama |

| Ukubekwa uphawu okuvundlile kufanelekile | Ifanele izicelo zangaphakathi nangaphandle |

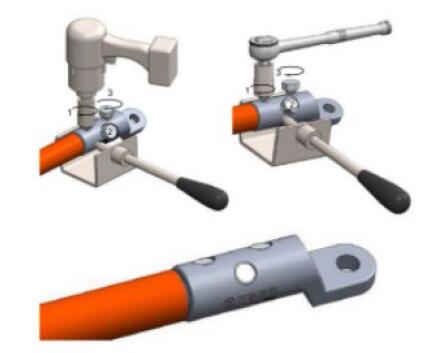

ukufakwa

▪ Awekho amathuluzi akhethekile adingekayo ukuze kufakwe, kudingeka isikrufu sesokhethi kuphela ukuze kufakwe;

▪ Uhlobo ngalunye lusebenzisa ubude obuncishisiwe obufanayo, okuhlanganisa nokuhlinzekwa kokufakiwe;

▪ Idizayini ye-torque egxilile ye-torque scissor head nut ukuqinisekisa ukuthintana okuthembekile nokuqinile;

▪ Isixhumi ngasinye noma isikhwama sekhebula sinomyalelo wokufaka ohlukile;

▪ Sincoma ukusebenzisa ithuluzi lokusekela (bona okunamathiselwe kwi-imeyili) ukuze uvimbele umqhubi ukuba angagobi.

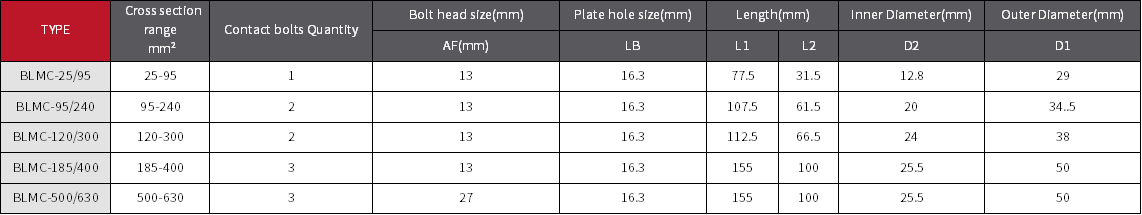

Ithebula lokukhetha

| Imodeli yomkhiqizo | I-wire cross section mm² | Usayizi (mm) | Izimbobo ezifakwayo ububanzi | Ibhawodi yokuxhumana Ubuningi | Imininingwane yekhanda le-bolt I-AF(mm) | Ubude bokucwecwa (Mm) | |||

| L1 | L2 | D1 | D2 | ||||||

| I-BLMT-25/95-13 | 25-95 | 60 | 30 | 24 | 12.8 | 13 | 1 | 13 | 34 |

| I-BLMT-25/95-17 | 25-95 | 60 | 30 | 24 | 12.8 | 17 | 1 | 13 | 34 |

| I-BLMT-35/150-13 | 35-150 | 86 | 36 | 28 | 15.8 | 13 | 1 | 17 | 41 |

| I-BLMT-35/150-17 | 35-150 | 86 | 36 | 28 | 15.8 | 17 | 1 | 17 | 41 |

| I-BLMT-95/240-13 | 95-240 | 112 | 60 | 33 | 20 | 13 | 2 | 19 | 70 |

| I-BLMT-95/240-17 | 95-240 | 112 | 60 | 33 | 20 | 17 | 2 | 19 | 70 |

| I-BLMT-95/240-21 | 95-240 | 112 | 60 | 33 | 20 | 21 | 2 | 19 | 70 |

| I-BLMT-120/300-13 | 120-300 | 120 | 65 | 37 | 24 | 13 | 2 | 22 | 70 |

| I-BLMT-120/300-17 | 120-300 | 120 | 65 | 37 | 24 | 17 | 2 | 22 | 70 |

| I-BLMT-185/400-13 | 185-400 | 137 | 80 | 42 | 25.5 | 13 | 3 | 22 | 90 |

| I-BLMT-185/400-17 | 185-400 | 137 | 80 | 42 | 25.5 | 17 | 3 | 22 | 90 |

| I-BLMT-185/400-21 | 185-400 | 137 | 80 | 42 | 25.5 | 21 | 3 | 22 | 90 |

| I-BLMT-500/630-13 | 500-630 | 150 | 95 | 50 | 33 | 13 | 3 | 27 | 100 |

| I-BLMT-500/630-17 | 500-630 | 150 | 95 | 50 | 33 | 17 | 3 | 27 | 100 |

| I-BLMT-500/630-21 | 500-630 | 150 | 95 | 50 | 33 | 21 | 3 | 27 | 100 |

| I-BLMT-800-13(eyenziwe ngokwezifiso) | 630-800 | 180 | 105 | 61 | 40.5 | 13 | 4 | 19 | 118 |

| I-BLMT-800-17(eyenziwe ngokwezifiso) | 630-800 | 180 | 105 | 61 | 40.5 | 17 | 4 | 19 | 118 |

| I-BLMT-800/1000-17 | 800-1000 | 153 | 86 | 60 | 40.5 | 17 | 4 | 13 | 94 |

| I-BLMT-1500-17 (eyenziwe ngokwezifiso) | 1500 | 200 | 120 | 65 | 46 | 17 | 4 | 19 | 130 |

Itheminali ye-torque

Amathuluzi okufaka owadingayo:

▪ Isokhethi engu-hexagon ngosayizi olungile we-A/F

▪ isikrufu se-ratchet noma isikrufu somthelela kagesi

noma isikrufu somthelela kagesi

▪ into enconywe kakhulu ukusekela ibhawudi lokusika uma ukhondatha egoba

Umhlahlandlela wokufaka

2. Ukufana kokugunda kwe-conductor.ubude bekhasi lomqhubi okufanele usikwe kubhekiselwe kumhlahlandlela oncomayo.

gwema ukusika umqhubi.

3.Ukufaka ikhondakta ngezansi kwetheminali yetorque ngokucophelela.

4.qinisa ibhawudi lokugunda, ulungise ikhondukta endaweni yokugcina.qinisa ibhawudi ukusuka ku-1-2-3