I-Automatic Splice

| Isixhumi esizenzakalelayo se-splice | |||||

| Uhlobo | I-AAAC(mm²) | Intambo evalekile engaphezulu (mm²) | I-ACSR(mm²) | Ibanga lobubanzi (mm) | Umbala |

| I-GL-401 | 4.68-6.7 | Okuluhlaza okwesibhakabhaka | |||

| I-GL-402A | 16 | 16 | 16 | 5.59-6.35 | Okubomvu |

| I-GL-4042A | 35 | 35 | 35 | 5.59-8.13 | Okubomvu |

| I-GL-404A | 35 | 35 | 35 | 5.84-8.60 | Okubomvu |

| I-GL-406A | 50 | 50 | 50 | 9.02-10.16 | Okuphuzi |

| I-GL4076A | 9.02-11.94 | Okuphuzi | |||

| I-GL-407 | 70 | 70 | 70 | 10.16-11.94 | Mnyama |

| I-GL-408 | 95 | 95 | 95 | 11.43-13.46 | Mnyama |

| I-GL-4098 | 11.43-15.11 | Mnyama | |||

| I-GL-409A | 120 | 120 | 120 | 12.83-15.11 | Mnyama |

| I-GL-410 | 150 | 150 | 150 | 15.32-16.92 | Okuhlaza |

| I-GL-411 | 150 | 150 | 150 | 16.74-18.39 | Okuhlaza |

| I-GL-412 | 185 | 185 | 185 | 18.34-20.19 | Emhlophe |

| I-GL-413 | 240 | 240 | 240 | 19.81-21.79 | Emhlophe |

| I-GLT-1316A | —- | —- | 120 | —- | Umbala wemvelo |

| I-GLT-1317A | —- | —- | 150 | —- | |

| I-GLT-1319A | —- | —- | 240 | —- | Okuluhlaza okwesibhakabhaka |

| I-GLT-1333A+ | 300 | Sicela usithinte | 240 | 21.34-23.37 | Umbala wemvelo |

| I-GLT-1355A+ | 300 | Sicela usithinte | 23.80-24.80 | Umbala wemvelo | |

| I-GLT-1385A+ | 400 | Sicela usithinte | 25.3-26.19 | Umbala wemvelo | |

| I-GLT-1441A+ | 500 | Sicela usithinte | 27.94-28.95 | Okubomvu | |

Uhlolojikelele

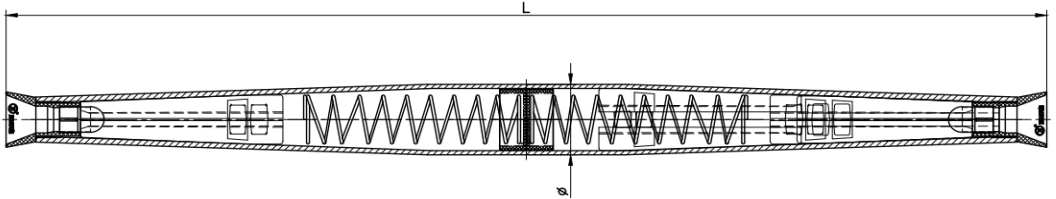

I-Aluminium Automatic Spliceisixhumi sekhebula silungele ukugcinwa nokulungiswa kolayini ophukile noma ulayini omusha.Isisetshenziswa esincike ku-tension lapho ulayini ufakwe khona okungenani u-10% wamandla alinganisiwe ocingo ukuze kuqinisekiswe uxhumano lukagesi oluthembekile, futhi lwamanje kudluliselwa komunye umkhawulo ngesiqeshana sentambo yocingo.I-taper yohlobo lwesixhumi esisheshayo esizenzakalelayo (isixhumi esizenzakalelayo esicindezelayo)

Isici

1.Ingakwazi ukumelana namandla aphelele ocingo ngokwalo

I-2.Umklamo wezindlu we-Hammer uqinisekisa ukunamathela kwamandla aphezulu kucingo

3.Isiqeshana socingo sangaphakathi sishunyekwe ocingweni lwangaphakathi

I-4.Ingahlinzeka nge-conductivity engalahleki kumqhubi

5.Isiqeshana socingo singakwazi ukuqhuba okwamanje endlini nge-conductivity ephezulu

6.Imihlathi ebambayo yesiqeshana socingo ingangena ungqimba lwe-oxide esele endaweni yocingo

7.Amaphoyinti okuxhumana amakhulu asiza ukuqeda ukushisa

I-8.I-meshing metal clamp igcina ukuhamba kahle kukagesi ngaphansi kwezimo ezihlukahlukene zokuhlukahluka kokucindezeleka

9.Awekho amathuluzi akhethekile okufakwa, akukho ukusebenza kwe-crimping

I-10.Elula ukufakwa komsebenzi bukhoma

11.Izinyathelo zokufaka zenziwe lula futhi nokuphepha kokusebenza kuthuthukiswa kakhulu

Umhlahlandlela wokufaka

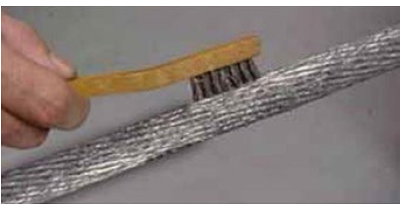

1. Susa isikhumba se-oxide ngebhulashi le-conductor.

2. Qiniseka ukuthi i-conductor ihlanzekile, iqondile, ayinawo ama-burrs

3.Linganisa ubude ukusuka ekugcineni kwe-knurl ukuya ekugcineni kwegayidi yefaneli, bese uyamakwa.

4. Ukufaka i-conductor ngokuqinile esitobhini esiphakathi.Ngemva kwalokho qiniseka ukuthi ucingo lulungisiwe.