I-Automatic Splice

| Isidibanisi se-splice esizenzekelayo | |||||

| Uhlobo | I-AAAC(mm²) | Umcingo ogqunyiweyo ongaphezulu (mm²) | I-ACSR(mm²) | Uluhlu lwedayamitha (mm) | Umbala |

| I-GL-401 | 4.68-6.7 | Luhlaza | |||

| I-GL-402A | 16 | 16 | 16 | 5.59-6.35 | Bomvu |

| I-GL-4042A | 35 | 35 | 35 | 5.59-8.13 | Bomvu |

| I-GL-404A | 35 | 35 | 35 | 5.84-8.60 | Bomvu |

| I-GL-406A | 50 | 50 | 50 | 9.02-10.16 | Lubhelu |

| GL4076A | 9.02-11.94 | Lubhelu | |||

| I-GL-407 | 70 | 70 | 70 | 10.16-11.94 | Mnyama |

| I-GL-408 | 95 | 95 | 95 | 11.43-13.46 | Mnyama |

| I-GL-4098 | 11.43-15.11 | Mnyama | |||

| I-GL-409A | 120 | 120 | 120 | 12.83-15.11 | Mnyama |

| I-GL-410 | 150 | 150 | 150 | 15.32-16.92 | Luhlaza |

| I-GL-411 | 150 | 150 | 150 | 16.74-18.39 | Luhlaza |

| I-GL-412 | 185 | 185 | 185 | 18.34-20.19 | Mhlophe |

| I-GL-413 | 240 | 240 | 240 | 19.81-21.79 | Mhlophe |

| I-GLT-1316A | —- | —- | 120 | —- | Umbala wendalo |

| I-GLT-1317A | —- | —- | 150 | —- | |

| I-GLT-1319A | —- | —- | 240 | —- | Luhlaza |

| GLT-1333A+ | 300 | Nceda uqhagamshelane nathi | 240 | 21.34-23.37 | Umbala wendalo |

| GLT-1355A+ | 300 | Nceda uqhagamshelane nathi | 23.80-24.80 | Umbala wendalo | |

| GLT-1385A+ | 400 | Nceda uqhagamshelane nathi | 25.3-26.19 | Umbala wendalo | |

| GLT-1441A+ | 500 | Nceda uqhagamshelane nathi | 27.94-28.95 | Bomvu | |

Isishwankathelo

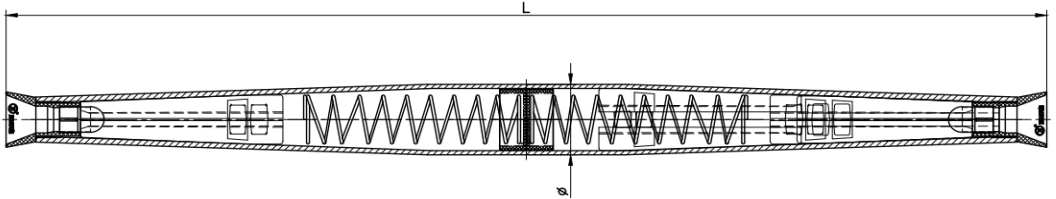

IAluminiyam ezenzekelayo iSpliceintambo isidibanisi ilungele ukugcinwa kunye nokulungiswa komgca owaphukileyo okanye umgca omtsha.Isixhobo esixhomekeke kuxinzelelo apho umgca ufakwe khona ubuncinci be-10% yoxinzelelo lwamandla ocingo ukuqinisekisa uqhagamshelo oluthembekileyo lombane, kwaye okwangoku igqithiselwe kwelinye icala ngekliphu yocingo yocingo.Uhlobo lwetaper oluzenzekelayo isinxibelelanisi esikhawulezayo (isixhobo esizenzekelayo soxinzelelo oluzenzekelayo)

Uphawu

1.Inokumelana namandla apheleleyo ocingo ngokwawo

I-2.Uyilo lwezindlu ze-Hammer luqinisekisa ukunamathela kwamandla aphezulu kwintambo

3.Ikliphu yocingo yangaphakathi ifakwe kucingo lwangaphakathi

4.Inokubonelela nge-conductivity engalahlekanga kumqhubi

I-5.Ikliphu yocingo inokuqhuba okwangoku kwizindlu ezine-conductivity ephezulu

6.Imihlathi ebambayo yekliphu yocingo inokugqobhoza umaleko oshiyekileyo weoksidi kumphezulu wocingo.

I-7.Amanqaku oqhagamshelwano amakhulu anceda ukukhupha ukushisa

8.I-meshing metal clamp igcina i-conductivity elungileyo yombane phantsi kweemeko ezahlukeneyo zokuhlukahluka koxinzelelo

I-9.Akukho zixhobo ezikhethekileyo zofakelo, akukho msebenzi we-crimping

10.Ilungele ukufakela umsebenzi ophilayo

11.Amanyathelo okufakela alula kwaye ukhuseleko lokusebenza luphuculwe kakhulu

Isikhokelo soFakelo

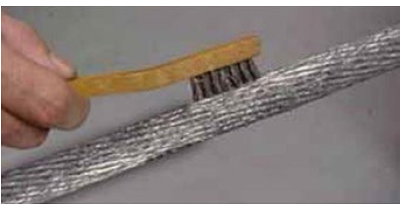

1. Susa ulusu lwe-oxide ngebrashi yomqhubi.

2. Qinisekisa ukuba i-conductor icocekile, ithe tye, ayinazo iibhula

3.Linganisa ubude ukusuka kwi-knurl ekupheleni ukuya ekupheleni kwe-funnel guide, emva koko imakishwe.

4. Ukufaka ngokuthe chu i-conductor kwindawo yokumisa.Emva koko qiniseka ukuba ucingo lulungisiwe.