Trending Products Welding Cable Lug - DT cable lug/ SC Terminals Connecting Tube – WANXIE

Trending Products Welding Cable Lug - DT cable lug/ SC Terminals Connecting Tube – WANXIE Detail:

Overview

Terminal connectors are used to connect tap conductor to power equipments (transformer, circuit breaker, circuit breaker, disconnect switch. etc ) or to all bushing of substation. Aluminum connectors are also used to connect the tap conductor of T-connector. The connectors inclede conpressive-type and bolted, both types have angle of 0°30°and 90°with the direction of tap conductor.

DTL series Al-Cu connection terminal is suitable for transition joint of distribution device Aluminum core cable and electric equipment. DL Aluminum is used for Aluminum terminal linking of Aluminum core cable and electric equipment. DT copper terminal is used for copper terminal linking of copper core cable and electric equipment. The products adopt friction welding workmanship, Our company supplies Cu-Al terminal and wire clamp made by explosive wedling technique. The products have features as high welding strength, excellent electric property, resistance to galvanic corrosion, long service life, never fracture, high safety, etc.

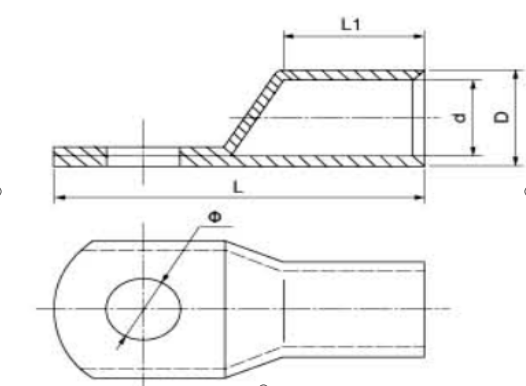

DT Aluminum cable lug

| DT Aluminum cable lug | |||||

| Type | Main size(mm) | ||||

| Φ | D | d | L | L1 | |

| DT-4 | 6.2 | 4.8 | 3.1 | 21.0 | 6.4 |

| DT-6 | 6.2 | 5.5 | 3.8 | 24.0 | 9.0 |

| DT-10 | 6.2 | 6.8 | 1.8 | 25.5 | 10.0 |

| DT-16 | 8.2 | 7.5 | 6.5 | 30.5 | 12.0 |

| DT-25 | 8.2 | 9.0 | 7.0 | 34.0 | 14.0 |

| DT-35 | 10.5 | 10.5 | 8.2 | 38.0 | 14.0 |

| DT-50 | 10.5 | 12.5 | 9.8 | 45.0 | 18.0 |

| DT-70 | 12.5 | 14.5 | 11.5 | 50.0 | 18.6 |

| DT-95 | 12.5 | 17.5 | 13.8 | 55.5 | 23.5 |

| DT-120 | 12.5 | 19.5 | 15.5 | 63.0 | 24.0 |

| DT-150 | 16.5 | 20.5 | 16.5 | 71.0 | 26.0 |

| DT-185 | 16.5 | 23.5 | 18.8 | 78.0 | 33.0 |

| DT-240 | 16.5 | 26.5 | 21.0 | 92.0 | 37.0 |

| DT-300 | 16.5 | 30.0 | 24.0 | 102.0 | 39.5 |

| DT-400 | 16.5 | 34.0 | 26.5 | 113.0 | 46.0 |

| DT-500 | 20.5 | 38.0 | 30.0 | 123.0 | 50.0 |

| DT-630 | 20.5 | 45.0 | 35.0 | 135.0 | 58.0 |

Cable range: 4-630mm2

SC Terminals Connecting Tube

SC(JGY) Copper Terminals Connecting Tube

Features:

JGY Copper Crimp Lug is made of with higher 99.9 percent pure copper tube T2 and coated with tin. Working temperature -55℃-150℃.

Application:

JGY Copper Crimp Lugs are suitable for the connection of copper conductors(section 1.5-1000mm2) in power cable with electronic equipment.

|

SC Tinned copper cable lug |

||||

|

Type |

Main size(mm) |

|||

|

Φ |

D |

d |

L |

|

|

SC-1.5 |

4.2, 5.2 |

3.5 |

1.8 |

21.0 |

|

SC-2.5 |

4.2, 5.2, 6.2 |

4.0 |

2.5 |

21.0 |

|

SC-4 |

5.2, 6.2 |

4.8 |

3.1 |

21.0 |

|

SC-6 |

5.2, 6.2, 8.2 |

5.5 |

3.8 |

24.0 |

|

SC-10 |

6.2, 8.2 |

6.8 |

4.8 |

25.5 |

|

SC-16 |

6.2, 8.2, 10.5 |

7.5 |

5.5 |

30.5 |

|

SC-25 |

6.2, 8.2, 10.5 |

9.0 |

7.0 |

34.0 |

|

SC-35 |

6.2, 8.2, 10.5, 12.5 |

10.5 |

8.2 |

38.0 |

|

SC-50 |

8.2, 10.5, 12.5 |

12.5 |

9.8 |

45.0 |

|

SC-70 |

8.2, 10.5, 12.5 |

14.5 |

11.5 |

50.0 |

|

SC-95 |

10.5, 12.5 |

17.5 |

13.8 |

55.5 |

|

SC-120 |

12.5, 16.5 |

19.5 |

15.5 |

63.0 |

|

SC-150 |

12.5, 16.5 |

20.5 |

16.5 |

71.0 |

|

SC-185 |

16.5 |

23.5 |

18.8 |

78.0 |

|

SC-240 |

16.5 |

23.5 |

21.0 |

92.0 |

|

SC-300 |

16.5, 20.5 |

30.0 |

24.0 |

102.0 |

|

SC-400 |

16.5, 20.5 |

34.0 |

26.5 |

113.0 |

|

SC-500 |

16.5, 20.5 |

38.0 |

30.0 |

123.0 |

|

SC-630 |

20.5 |

45.0 |

35.0 |

135.0 |

|

SC-800 |

22.5 |

50.0 |

39.0 |

170.0 |

|

SC-1000 |

22.5 |

56.0 |

44.0 |

200.0 |

Cable range:1.5-1000mm2

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for Trending Products Welding Cable Lug - DT cable lug/ SC Terminals Connecting Tube – WANXIE, The product will supply to all over the world, such as: Nicaragua, Somalia, British, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.