Automatic Splice

| Sehokedi se ikemetseng sa splice | |||||

| Mofuta | AAAC(mm²) | Mohala o kentsoeng ka holim'a hlooho (mm²) | ACSR(mm²) | bophara ba bophara (mm) | Mmala |

| GL-401 | 4.68-6,7 | Boputsoa | |||

| GL-402A | 16 | 16 | 16 | 5.59-6,35 | Khubedu |

| GL-4042A | 35 | 35 | 35 | 5.59-8.13 | Khubedu |

| GL-404A | 35 | 35 | 35 | 5.84-8.60 | Khubedu |

| GL-406A | 50 | 50 | 50 | 9.02-10.16 | Bosehla |

| GL4076A | 9.02-11.94 | Bosehla | |||

| GL-407 | 70 | 70 | 70 | 10.16-11.94 | Ntsho |

| GL-408 | 95 | 95 | 95 | 11.43-13.46 | Ntsho |

| GL-4098 | 11.43-15.11 | Ntsho | |||

| GL-409A | 120 | 120 | 120 | 12.83-15.11 | Ntsho |

| GL-410 | 150 | 150 | 150 | 15.32-16.92 | Botala |

| GL-411 | 150 | 150 | 150 | 16.74-18.39 | Botala |

| GL-412 | 185 | 185 | 185 | 18.34-20.19 | Bosoeu |

| GL-413 | 240 | 240 | 240 | 19.81-21.79 | Bosoeu |

| GLT-1316A | —- | —- | 120 | —- | 'Mala oa tlhaho |

| GLT-1317A | —- | —- | 150 | —- | |

| GLT-1319A | —- | —- | 240 | —- | Boputsoa |

| GLT-1333A+ | 300 | Ka kopo, buisana le rona | 240 | 21.34-23.37 | 'Mala oa tlhaho |

| GLT-1355A+ | 300 | Ka kopo, buisana le rona | 23.80-24.80 | 'Mala oa tlhaho | |

| GLT-1385A+ | 400 | Ka kopo, buisana le rona | 25.3-26.19 | 'Mala oa tlhaho | |

| GLT-1441A+ | 500 | Ka kopo, buisana le rona | 27.94-28.95 | Khubedu | |

Kakaretso

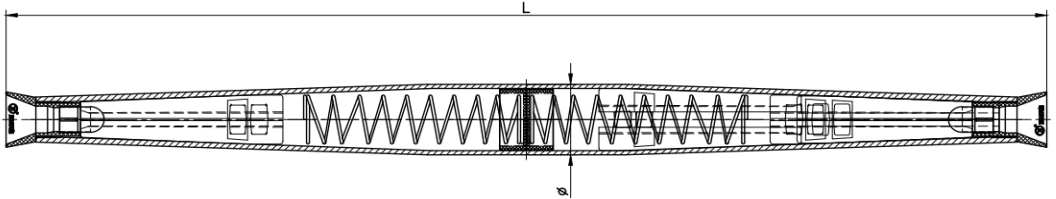

Aluminium Automatic Splicesehokedi sa thapo se loketse bakeng sa tlhokomelo le tokiso ya mohala o robehileng kapa mohala o motjha.Sesebediswa se itshetlehileng ka tsitsipano moo mohala o kenngwang bonyane 10% ya matla a lekantsweng a terata ho etsa bonnete ba kgokelo ya motlakase e tshepehang, mme ya jwale ke e fetisetsoang pheletsong enngwe ka sekotwana sa terata sa terata.Sehokelo se potlakileng sa mofuta oa taper (sehokelo sa othomathike se felletseng sa tsitsipano)

Sebopeho

1.E ka mamella matla a feletseng a terata ka boeona

2.Moqapi oa matlo a hammer o tiisa ho khomarela matla a phahameng ho terata

3.Sekotwana sa terata se ka hare se kentsoe ka har'a terata e ka hare

4.E ka fana ka conductivity e sa lahleheloeng ke mokhanni

5.Sekotwana sa terata se ka tsamaisa hona joale ho ea matlong a nang le conductivity e phahameng

6. Mehlahare e koalang ea sekotwana sa terata e ka phunyeletsa lera le setseng la oxide holim'a terata.

7.Lintlha tse kholo tsa ho kopana li thusa ho senya mocheso

8.The meshing metal clamp e boloka conductivity e ntle ea motlakase tlas'a maemo a sa tšoaneng a phapang ea tsitsipano

9.Ha ho lisebelisoa tse khethehileng tsa ho kenya, ha ho ts'ebetso ea crimping

10.Convenient bakeng sa ho kenya mosebetsi o phelang

11.Mehato ea ho kenya e nolofalitsoe mme polokeho ea ts'ebetso e ntlafatsoa haholo

Tataiso ea ho Kena

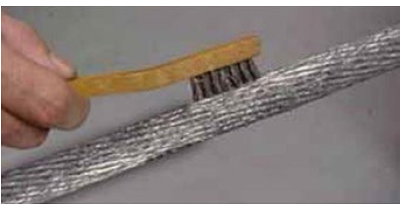

1. Tlosa letlalo la oxide ka brush ea conductor.

2. Etsa bonnete ba hore conductor e hloekile, e otlolohile, ha e na li-burrs

3.Lekanya bolelele ho tloha pheletsong ea knurl ho isa pheletsong ea tataiso ea fane, ebe e tšoauoa.

4. E tsitsitse ho kenya conductor setsing sa bohareng.Ka mor'a moo etsa bonnete ba hore terata e tsitsitse.