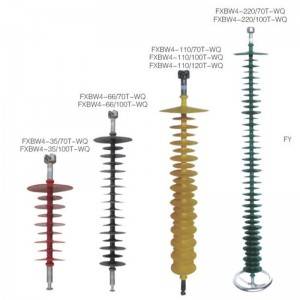

Rod composite tension insulator

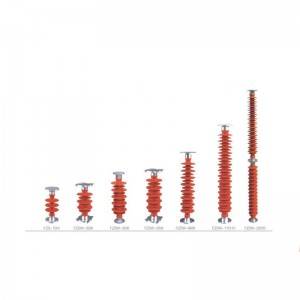

Polymer Insulator Character

1.1 High mechanical strength;

1.2 Good performance of hydrophobicity and anti-pollution;

1.3 Excellent electrical Performance;

1.4 Small volume and light weight.

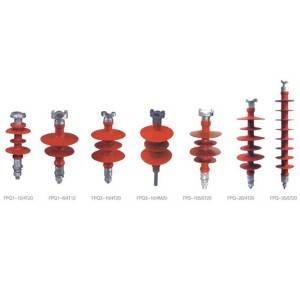

TID polymer Insulator Character

2.1 We adopt the advanced injection producing technology for housing and the design of the shed adopt unique aerodynamics principle.

2.2 Good Raw material :

We use HTV silicone rubber which hydrophobicity can reach to HC1 level

We use hot dip Galvanizing steel fitting ,the thickness of the zinc more than 100 μm.

We use ECR rod as the core which is high acid resistant. 7200Hr testing passed .

2.3 Special marking design.

We use the double seal design between the rubber and the fitting.

We can mark your logo on the fitting or rubber.

2.4 Excellent Manufacture Technology:

Perfect match between fitting and rod

Perfect bound between silicone rubber and the rod

| FXBW4-XX Rod composite tension insulator | |||||||

| Type | Rated voltage(KV) | Rated Machinery load(KN) | Structural height(mm) | Insulation distance(mm) | Minimum nominal creepage distance (mm) | lightning impulse withstand voltage (peak kv) | 1min Power-frequency withstand voltage (RMS) |

| FXBW4-1/70XX | 1 | 70 | 300 | 110 | 280 | 30 | 7 |

| FXBW4-6/70XX | 6 | 70 | 340 | 150 | 360 | 60 | 25 |

| FXBW4-10/70XX | 10 | 70 | 380 | 200 | 480 | 95 | 45 |

| FXBW4-15/70XX | 15 | 70 | 420 | 240 | 600 | 110 | 60 |

| FXBW4-20/70XX | 20 | 70 | 460 | 290 | 720 | 130 | 70 |

| FXBW4-24/70XX | 24 | 70 | 460 | 290 | 720 | 150 | 75 |

| FXBW4-28/70XX | 28 | 70 | 640 | 335 | 840 | 180 | 85 |

| FXBW4-33/70XX | 33 | 70 | 680 | 380 | 960 | 205 | 90 |

| FXBW4-35/70XX | 35 | 70 | 680 | 380 | 960 | 230 | 95 |

| FXBW4-35/70XX | 35 | 70 | 680 | 380 | 960 | 230 | 95 |