preformed grip dead-end grip for ADSS cable

Overview

Tension Clamps are designed to connect ADSS cables and poles/towers . Armor rods can provide protection and cushioning to the ADSS cables. The special design of Preformed rods makes ensure that Tension Clamps can’t cause undue stress to the ADSS cables, so as to ensure the normal lifetime of cables system.

Preformed Tension Clamp are designed to connect ADSS cables and poles/towers . Armor rods can provide protection and cushioning to the ADSS cables. The special design of Preformed rods makes ensure that Tension Clamps can’t cause undue stress to the ADSS cables, so as to ensure the normal lifetime of cables system.

Tension Clamp are designed to connect OPGW cables and tensile poles (or towers). Armor rods can protect and provide cushioning to the OPGW cables. The special design of Armor rods makes ensure that Tension Clamps can not cause undue stress to the OPGW cables,so that the normal lifetime of cable system is ensured.

Matching hardware

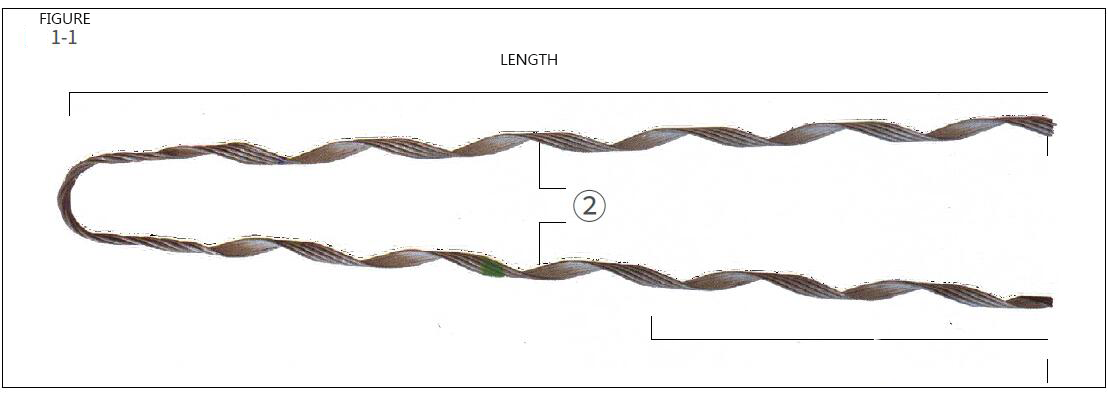

Heart-shaped ring (picture 1-1) (table 1-1) (circle 1-2) (table 1-2)

Body: Hot-dip galvanized ductile iron Bolt: Made of hot-dip galvanized steel

Split pin: stainless copper

Heart-shaped ring

|

Product number |

Reference mark |

Breaking strength |

weight |

Size (mm) |

||||

|

A |

B |

C |

D |

E |

||||

|

TC-12 |

TC-12 |

120 |

0.9 |

107 |

48 |

24 |

57 |

M16 |

|

TC-16 |

TC-16 |

156 |

1.7 |

124 |

57 |

25.4 |

64 |

M18 |

|

TC-16 |

TC-16 |

156 |

1.7 |

124 |

57 |

25.4 |

64 |

M16 |

Heart ring

|

Product number |

Reference mark |

Breaking strength |

weight |

Size (mm) |

|||||

|

A |

B |

C |

D |

E |

|||||

|

TC-05 |

TC-05 |

50 |

0.33 |

60 |

45 |

20 |

40 |

16 |

|

|

TC-07 |

TC-07 |

70 |

0.44 |

60 |

45 |

20 |

42 |

16 |

|

Note

▪ Do not overlap the wire clips. Lapping on the wires before and after the clamp is allowed:

▪ Do not use wire clamps for overhead ground wires;

▪ After the initial installation, do not use the wire clamp again:

▪ The direction of rotation of the wire clamp and the wire should be the same. The standard clamp is right-handed, if you need left-handed products, please consult the company.

Selection table of strain clamp for pre-twisted insulated conductors (1)

|

Product number |

Applicable wire diameter range (mm) |

Applicable wire model below 1kV GB12527-90 |

Applicable wire model below 10kV GB 14049-93 thin insulation |

Reference length (mm) |

Color code |

Optional matching hardware |

|

|

The smallest |

maximum |

||||||

|

DN-3510 |

5.82 |

6.53 |

10 |

460 |

Orange |

TC-05 |

|

|

DN-3511 |

6.55 |

7.34 |

16 |

530 |

yellow |

||

|

DN-3513 |

8.28 |

9.25 |

25 |

690 |

green |

||

|

DN-3514 |

9.26 |

10.39 |

35 |

690 |

yellow |

||

|

DN-3515 |

10.40 |

11.68 |

50 |

740 |

blue |

||

|

DN-3516 |

11.69 |

13.11 |

70 |

25 |

790 |

Orange

|

|

|

35 |

|||||||

|

DN-3517 |

13.12 |

14.66 |

50 |

860 |

purple |

||

|

DN-3100 |

14.67 |

16.59 |

95 |

70 |

889 |

blue

|

|

|

120 |

|||||||

|

DN-3101 |

16.60 |

18.77 |

150 |

95 |

980 |

red |

|

|

DN-3102 |

18.78 |

21.26 |

185 |

120 |

1016 |

Brown

|

TC-07 |

|

150 |

|||||||

|

DN-3103 |

21.27 |

24.05 |

240 |

185 |

1016 |

green |

TC-12 |

|

DN-3104 |

24.06 |

27.20 |

240 |

1016 |

black |

||

|

300 |

|||||||

Table 1-4 Selection table of strain clamp for pre-twisted insulated conductors (2)

|

Product number |

Applicable wire diameter range (mm) |

Applicable wire model below 1kV GB12527-90 |

Applicable wire model below 10kV GB 14049-93 thin insulation |

Reference length (mm) |

Color code |

|

|

Mininum |

Maximum |

|||||

|

NL-35/JY |

14.67 |

16.59 |

35 |

889 |

blue

|

TC-05 |

|

NL-50/JY |

50 |

|||||

|

NL-70/JY |

16.60 |

18.77 |

70 |

980 |

red |

|

|

NL-95/JY |

18.78 |

21.26 |

95 |

1016 |

Brown

|

TC-07 |

|

NL-120/JY |

120 |

|||||

|

NL-150/JY |

21.27 |

24.05 |

150 |

1016 |

green |

TC-12 |

|

NL-185/JY |

24.06 |

27.20 |

185 |

1016 |

black

|

|

|

NL-240/JY |

240 |

|||||

|

NL-300/JY |

27.21 |

30.78 |

300 |

1016 |

purple |

|

Note: The meaning of letters and numbers in the model: N- strain clamp; L- spiral pre-twisted type: “-” is the applicable wire model JY- insulated wire.

The selection of the TCB model of the optional matching hardware is related to the rated breaking force of the wire.

The selection of strain clamp is subject to the actual wire diameter.

Table 1-5 Selection table of pre-stranded conductor strain clamp (for steel core aluminum stranded wire)

|

Product number |

Applicable wire diameter range (mm) |

Applicable wire model below 1kV GB12527-90 |

Reference length (mm) |

Clamp weight (kg) |

Color code |

Optional matching hardware |

|

|

Minimum |

maximum |

||||||

|

NL-16/3 |

5.17 |

5.79 |

16/3 |

444 |

0.1 |

Brown |

TC-05 |

|

NL-25/4 |

6.54 |

7.34 |

25/4 |

546 |

0.1 |

yellow |

|

|

NL-35/6 |

7.35 |

8.26 |

35/6 |

622 |

0.2 |

red |

|

|

NL-50/8 |

9.26 |

10.39 |

50/8 |

685 |

0.2 |

yellow |

|

|

NL-70/10 |

10.40 |

11.68 |

70/10 |

736 |

0.3 |

blue |

|

|

NL95/15 |

13.12 |

14.66 |

95/15 |

876 |

0.6 |

red

|

TC-07 |

|

NL-95/20 |

95/20 |

||||||

|

NL-120/7 |

120/7 |

||||||

|

NL-120/20 |

14.67 |

16.59 |

120/20 |

889 |

0.8 |

black

|

|

|

NL-120/25 |

120/25 |

TC-12 |

|||||

|

NL-150/8 |

150/8 |

||||||

|

NL-150/20 |

16.60 |

18.77 |

150/20 |

1016 |

1.1 |

green |

|

|

NL-150/25 |

150/25 |

||||||

|

NL-150/35 |

150/35 |

||||||

|

NL-185/10 |

185/10 |

||||||

|

NL-185/25 |

18.78 |

21.26 |

185/25 |

1155 |

1.7 |

Orange

|

|

|

NL-185/30 |

185/30 |

||||||

|

NL-185/45 |

185/45 |

||||||

|

NL-210/10 |

210/10 |

||||||

|

NL-210/25 |

210/25 |

||||||

|

NL-210/35 |

210/35 |

||||||

|

NL-210/50 |

210/50 |

||||||

|

NL-240/30 |

21.27 |

24.05 |

240/30 |

1270 |

2.3 |

blue

|

TC-16 |

|

NL-240/40 |

240/40 |

||||||

|

NL-300/15 |

300/15 |

||||||

|

NL-300/20 |

300/20 |

||||||

|

NL-300/25 |

24.06 |

27.20 |

300/25 |

1442 |

3.0 |

Brown |

|

|

NL-300/40 |

300/40 |

||||||

|

NL-300/50 |

300/50 |

||||||

Note: The meaning of letters and numbers in the model: N- tension clamp; L- spiral pre-twisted type; after “-” is the applicable wire model; LGJ- steel core aluminum stranded wire.

This table only lists some products. If you need products with other specifications, please consult the company.

In principle, pre-twisted conductor strain clamps are only used in overhead lines with voltage levels of 110kV and below.

Table 1-6 Selection table of pre-twisted wire tension clamp (for aluminum stranded wire)

|

Product number |

Applicable wire diameter range (mm) |

Applicable wire type (GB1179-83) Aluminum stranded wire (LJ) |

Reference length (mm) |

Clamp weight |

Color code |

Optional matching hardware |

|

|

Minimum |

Maximum |

||||||

|

NL-16/LJ |

4.62 |

5.16 |

16 |

406 |

0.1 |

blue |

TC-05 |

|

NL-25/LJ |

5.80 |

6.53 |

25 |

444 |

0.1 |

Orange |

|

|

NL-35/LJ |

7.35 |

8.26 |

35 |

622 |

0.2 |

red |

TC-07 |

|

NL-50/LJ |

8.27 |

9.25 |

50 |

685 |

0.2 |

green |

TC-12 |

|

NL-70/LJ |

10.40 |

11.68 |

70 |

736 |

0.4 |

blue |

|

|

NL-95/LJ |

11.69 |

13.22 |

95 |

800 |

0.4 |

Orange |

|

|

NL-120/LJ |

13.12 |

14.66 |

120 |

876 |

0.6 |

red |

|

|

NL-150/LJ |

14.67 |

16.59 |

150 |

889 |

0.8 |

black |

|

|

NL-185/LJ |

16.60 |

18.77 |

185 |

1016 |

1.1 |

green |

|

|

NL-210/LJ |

16.60 |

18.77 |

210 |

1016 |

1.1 |

green |

|

|

NL-240/LJ |

18.78 |

21.26 |

240 |

1155 |

1.7 |

Orange |

|

|

NL-300/LJ |

21.27 |

24.05 |

300 |

1270 |

2.3 |

blue |

TC-16 |

|

NL-400/LJ |

24.06 |

27.20 |

400 |

1422 |

3.0 |

Brown |

|

|

NL-500/LJ |

27.21 |

30.78 |

500 |

1651 |

4.9 |

Orange |

|

Note: The meaning of letters and numbers in the model: N- tensile clamp; L- spiral pre-twisted type: “One” is the applicable wire model; LJ- aluminum stranded wire.

This table only lists some products. If you need products with other specifications, please consult the company.