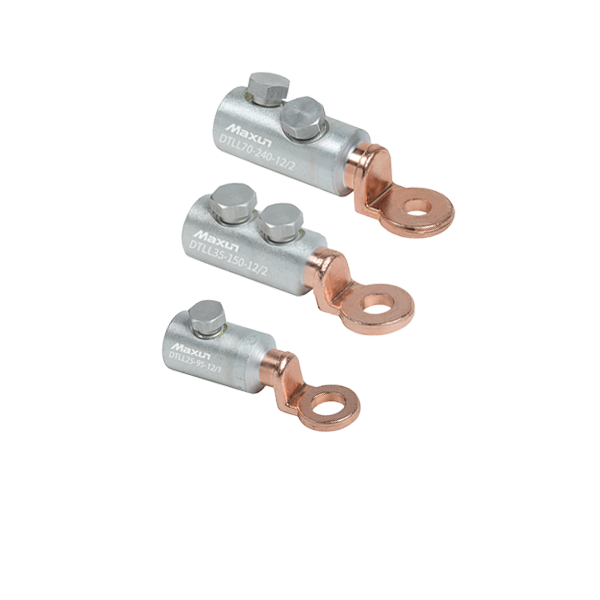

DTLL Bimetallic mechanical lug

Raw material

Made of pure copper and aluminum bars, the material is dense;

Connection method

The product is connected to the cable using a crimping process for reliable connection.

Use range and application field

It is suitable for connecting 35 KV (Um=40.5kV) and below power cable conductors to the end of the electric device. Other wires and cables for fixed laying can also be used.

Structural features

▪ High mechanical strength: using high-strength aluminum alloy and T2 copper material, after heat treatment and welding, the tensile strength can reach 260MPa;

▪ Good electrical performance: Pass 1000 thermal cycles and 6 short circuit tests;

▪ Span design: one model is suitable for cables with multiple diameters, reducing inventory quantity;

▪ Constant crimping force: The torque bolt is equipped with a specific shearing torque, and the hexagonal head will automatically break when the preset is reached, and the wire will not be damaged;

▪ Simple installation: it can be installed with a wrench or socket wrench;

▪ Extend life: oil-blocking design, conductive paste is placed inside, effectively reducing contact resistance, anti-oxidation and anti-corrosion.

Product property: Due to the coupling effect when Aluminum comes in contact with Copper, corrosion wil happen in a short time. Currently the best solution is to use Aluminum-Copper bi-metallic connectors. A bimetallic lug should be used for termination. the friction welding is well done. its copper and aluminum are excessively located at the round bar (the inner pin type is generally located at the flat plate), so it has good mechanical strength and electrical properties. And its barrel capped is filled with joint electric compound TO avoid oxidization. the type test is in accordance with IEC 61328-1.

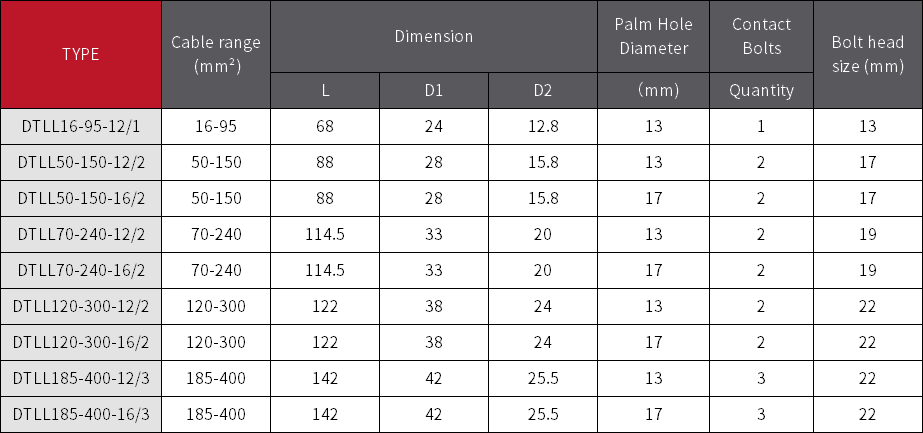

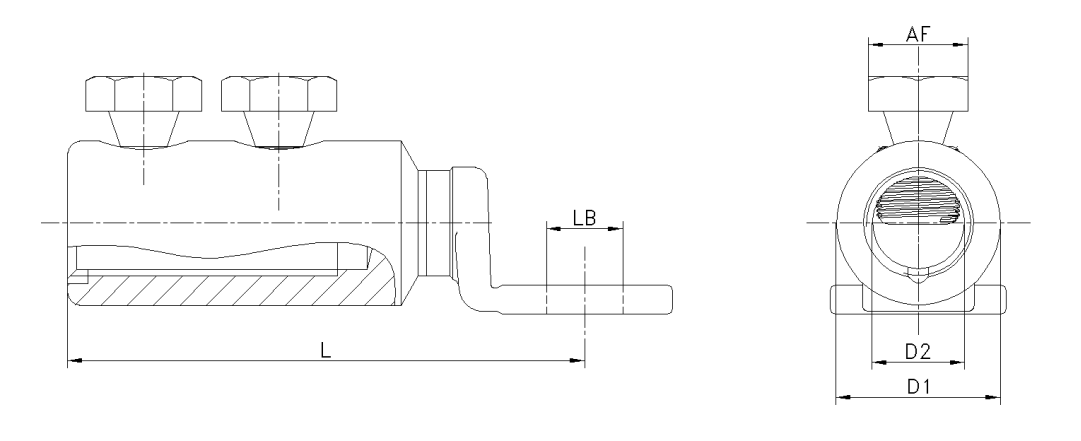

Selection table