Mechanical lug Shear Bolt Lug

Overview

Torque terminals are specially designed to handle the connection between wires and equipment.

The unique shear bolt mechanism provides a consistent and reliable stopping point. Compared with traditional crimping hooks, it is super fast and super efficient, and ensures a consistent predetermined shear moment and compression force.

The torsion terminal is made of tin-plated aluminum alloy and has an inner groove-shaped wall surface.

The notable feature is that it can save labor and enhance the electrical and mechanical performance.

▪ Material: tinned aluminum alloy

▪ Working temperature: -55℃ to155℃ -67 ℉ to 311 ℉

▪ Standard: GB/T 2314 IEC 61238-1

Features and advantages

▪ Wide range of applications

▪ Compact design

▪ It can be used with almost all types of conductors and materials

▪ Constant torque shearing head nut guarantees good electrical contact performance

▪ It can be easily installed with a standard socket wrench

▪ Pre-engineered design for perfect installation on medium voltage cables up to 42kV

▪ Good over-current and anti-short-term current impact capability

Overview

The terminal body is made of a high-tensile tin-plated aluminum alloy. The terminal is suitable for outdoor and indoor applications, and can provide different size specifications.

|

Features and advantages of mechanical lugs and connectors |

Function |

|

Wide application range and strong versatility |

For example, three specifications can cover 25mm2 to 400mm2 conductors. |

|

The body is made of high-tensile tinned aluminum alloy |

And it can be used with almost every type of conductor and material. |

|

The bolts are made of special aluminum alloy |

Good contact characteristics, can realize the connection between the copper conductor and the aluminum conductor. |

|

Compact design |

Only need a small installation space, especially suitable for large-scale applications. |

|

Tubular spiral design inside the body to improve contact performance |

Excellent electrical performance. |

|

Centering hole and insert |

The conductor oxide layer is split. |

|

Constant torque shear head nut |

The plug-in piece adjusts one size of the connection or terminal suitable for more types of wires. |

|

Lubricated nut |

The inserts help the conductor to be better centered and will not deform the conductor when the bolt is tightened. |

|

Special features of mechanical terminals |

|

|

Long handle |

With extra long length, it can be used as a moisture barrier |

|

Horizontal sealing is suitable |

Suitable for indoor and outdoor applications |

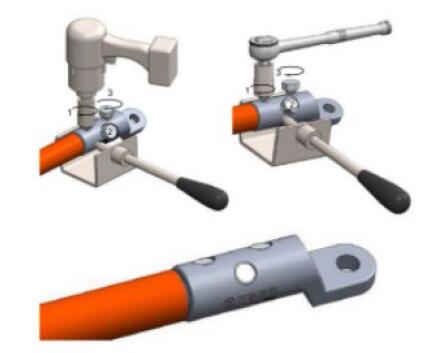

installation

▪ No special tools are required for installation, only a socket wrench is needed for installation;

▪ Each type uses the same reduced length, including the provision of inserts;

▪ Hierarchical fixed torque scissor head nut design to ensure reliable and firm contact;

▪ Each connector or cable lug has a separate installation instruction;

▪ We recommend using a support tool (see attachment) to prevent the conductor from bending.

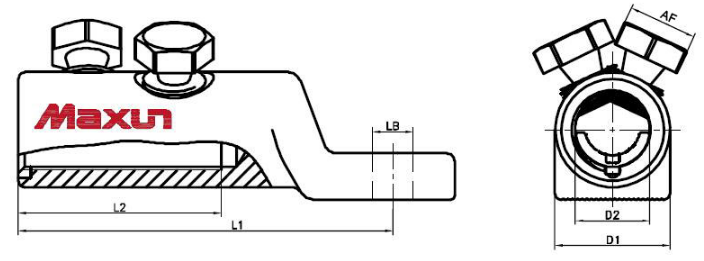

Selection table

|

Product model |

Wire cross section mm² |

Size (mm) |

Mounting holes diameter |

Number of Bolt |

Bolt Across Flat AF(mm) |

Peeling length (mm) |

|||

|

L1 |

L2 |

D1 |

D2 |

||||||

|

BLMT-25/95-13 |

25-95 |

60 |

30 |

24 |

12.8 |

13 |

1 |

13 |

34 |

|

BLMT-25/95-17 |

25-95 |

60 |

30 |

24 |

12.8 |

17 |

1 |

13 |

34 |

|

BLMT-35/150-13 |

35-150 |

86 |

36 |

28 |

15.8 |

13 |

1 |

17 |

41 |

|

BLMT-35/150-17 |

35-150 |

86 |

36 |

28 |

15.8 |

17 |

1 |

17 |

41 |

|

BLMT-95/240-13 |

95-240 |

112 |

60 |

33 |

20 |

13 |

2 |

19 |

70 |

|

BLMT-95/240-17 |

95-240 |

112 |

60 |

33 |

20 |

17 |

2 |

19 |

70 |

|

BLMT-95/240-21 |

95-240 |

112 |

60 |

33 |

20 |

21 |

2 |

19 |

70 |

|

BLMT-120/300-13 |

120-300 |

120 |

65 |

37 |

24 |

13 |

2 |

22 |

70 |

|

BLMT-120/300-17 |

120-300 |

120 |

65 |

37 |

24 |

17 |

2 |

22 |

70 |

|

BLMT-185/400-13 |

185-400 |

137 |

80 |

42 |

25.5 |

13 |

3 |

22 |

90 |

|

BLMT-185/400-17 |

185-400 |

137 |

80 |

42 |

25.5 |

17 |

3 |

22 |

90 |

|

BLMT-185/400-21 |

185-400 |

137 |

80 |

42 |

25.5 |

21 |

3 |

22 |

90 |

|

BLMT-500/630-13 |

500-630 |

150 |

95 |

50 |

33 |

13 |

3 |

27 |

100 |

|

BLMT-500/630-17 |

500-630 |

150 |

95 |

50 |

33 |

17 |

3 |

27 |

100 |

|

BLMT-500/630-21 |

500-630 |

150 |

95 |

50 |

33 |

21 |

3 |

27 |

100 |

|

BLMT-800-13 (custom made) |

630-800 |

180 |

105 |

61 |

40.5 |

13 |

4 |

19 |

118 |

|

BLMT-800-17 (custom made) |

630-800 |

180 |

105 |

61 |

40.5 |

17 |

4 |

19 |

118 |

|

BLMT-800/1000-17 |

800-1000 |

153 |

86 |

60 |

40.5 |

17 |

4 |

13 |

94 |

|

BLMT-1500-17 (custom made) |

1500 |

200 |

120 |

65 |

46 |

17 |

4 |

19 |

130 |

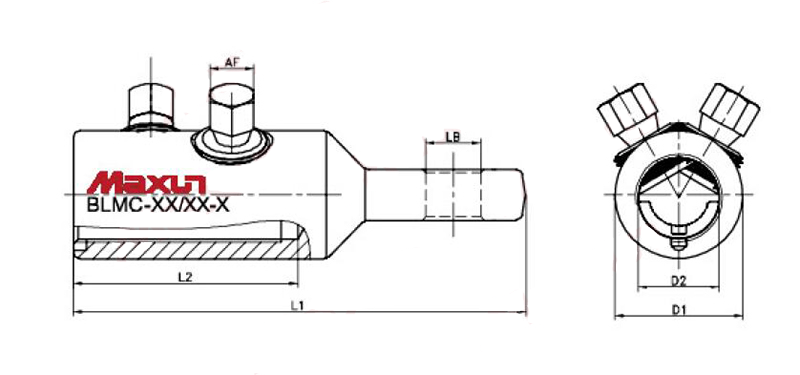

Torque terminal

| TYPE | Cross section range mm² |

Number of Contact bolts | Bolt head size(mm) | Plate hole size(mm) | Length(mm) | Inner Diameter(mm) | Outer Diameter(mm) | |

| AF(mm) | LB | L1 | L2 | D2 | D1 | |||

| BLMC-25/95 | 25-95 | 1 | 13 | 16.3 | 77.5 | 31.5 | 12.8 | 29 |

| BLMC-95/240 | 95-240 | 2 | 13 | 16.3 | 107.5 | 61.5 | 20 | 34..5 |

| BLMC-120/300 | 120-300 | 2 | 13 | 16.3 | 112.5 | 66.5 | 24 | 38 |

| BLMC-185/400 | 185-400 | 3 | 13 | 16.3 | 155 | 100 | 25.5 | 50 |

| BLMC-500/630 | 500-630 | 3 | 27 | 16.3 | 155 | 100 | 33 | 50 |

The installation tools you required:

▪ Hexagon socket in correct size of A/F

▪ Ratchet wrench  or electric impact wrench

or electric impact wrench

▪ Highly recommended use the fixture for supporting the cutting bolt in case of conductor bending

Installation Guide

2. The conductor shear end uniformity. the peel length of the conductor which should be cut referring to the recommending guide.

avoid to cut the conductor.

3.Inserting the conductor at the bottom of the torque terminal carefully.

4.Tighten the shear bolt, fixed the conductor to the terminal. the tighten the bolt from 1-2-3