CAPG Bimetal Parallel groove clamp

Overview

The groove connector is used for bearingless connection and offset of aluminum stranded wire and aluminum stranded wire. It is used with insulation cover to protect and insulate the wire

Parallel groove clamps are mainly used for transmitting current between the interconnected conductors. Besides this main area of application parallel groove clamps are also used for safety loops and therefore they must provide an adequate mechanical holding strength.

If conductors made of different materials are to be connected this can be done by using bimetal aluminium copper PG clamp. In bimetal PG clamps, the two bodies are made out of high strength aluminium alloy, and to tight a copper conductor, one groove is made with aluminium alloy and welded by hot forged bimetallic sheet . The bolts are made out of hard steel (8.8).

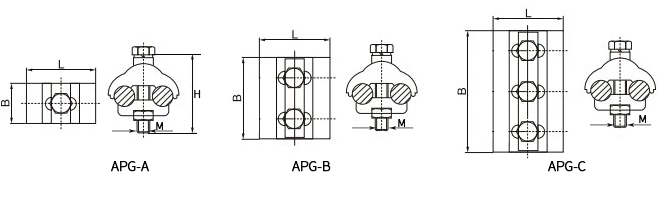

| Bimetal Parallel groove clamp | ||||||||

| Type | Cable range | Main size(mm) | Bolt Qty | |||||

| Al | Cu | L | B | H | R | M | ||

| CAPG-A1 | 16-70 | 6-50 | 25 | 42 | 40 | 7/5 | 8 | 1 |

| CAPG-A2 | 25-150 | 10-95 | 30 | 46 | 50 | 7.5/6 | 8 | 1 |

| CAPG-B1 | 16-70 | 6-50 | 40 | 42 | 45 | 7/5 | 8 | 2 |

| CAPG-B2 | 25-150 | 10-95 | 50 | 46 | 50 | 7.5/6 | 8 | 2 |

| CAPG-B3 | 35-200 | 16-185 | 62 | 58 | 60 | 10/9 | 10 | 2 |

| CAPG-C1 | 16-70 | 6-50 | 60 | 42 | 45 | 7/5 | 8 | 3 |

| CAPG-C2 | 16-150 | 10-95 | 70 | 46 | 50 | 7.5/6 | 8 | 3 |

| CAPG-C3 | 35-240 | 25-185 | 90 | 58 | 60 | 10/9 | 10 | 3 |

| CAPG-C4 | 35-300 | 35-240 | 105 | 65 | 70 | 13/10 | 10 | 3 |

Parallel -groove clamp combined channel connector is applicable to weight disburdening connection of overhead aluminium wire and splicing steel wire. BTL series copper-aluminium transitional combined channel connecter is applicable to the transitional connection of copper applicable to branching connection of different-section copper wire in section 16-240.

Features And Benefits:

1.High strength, corrosion resistant aluminium alloy and forging bi-metal.

2.Tooth type, small contact resistance, reliable connection.

3.Will not fall any part during assembly.

4.Hold a large area of arc, the contact surface will be closer which will improve the grip strength between clamps and conductors.