aluminum die casting

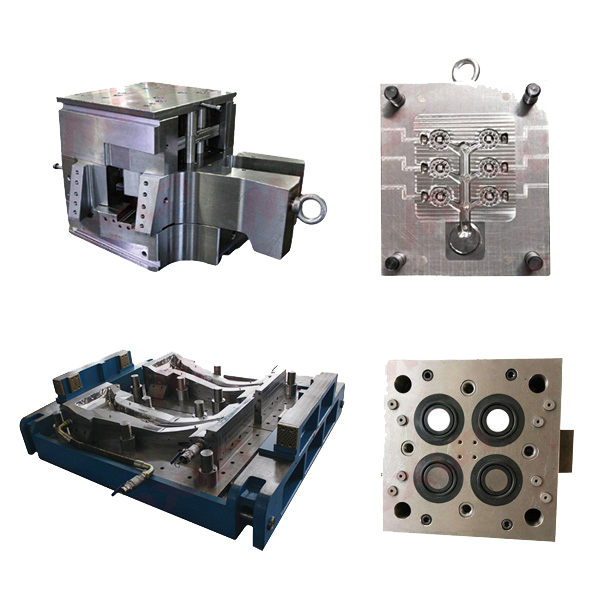

Aluminum Die Casting

Aluminum Die Casting is a process of injection of Aluminum or Aluminum Alloys under pressure, which produces parts in high volume at low costs.Aluminum castings are lightweight and able to withstand the highest operating temperatures of all die cast alloys.There are two processes of Aluminum die casting: hot chamber and cold chamber.A complete cycle can vary from one second for small components to minutes for a casting of large part, making aluminum die casting the fastest technique available for producing precise aluminum & aluminum alloy parts.

Designed capacity:

A good design is the heart of a mold, pays special attention to the mold construction,cooling

channels and moving mechanisms to ensure the highest quality parts are delivered from its mold at the minimum

cycle time.

Service:

Our Engineering Department will maintain responsibility for your project throughout the entire process.

From initial concept discussions through production, packaging, and shipping, all phases of the process are continuously

being evaluated to provide you with the absolute best overall value.

Quality control:

We have professional quality control personnel, several sets of 3D measuring instruments /2 D measuring instruments

and other high precision testing equipment, for each process of the product Inspection to ensure the quality of products in each process.